Premium camera's Precision in Every Module, Innovation at Your Fingertips

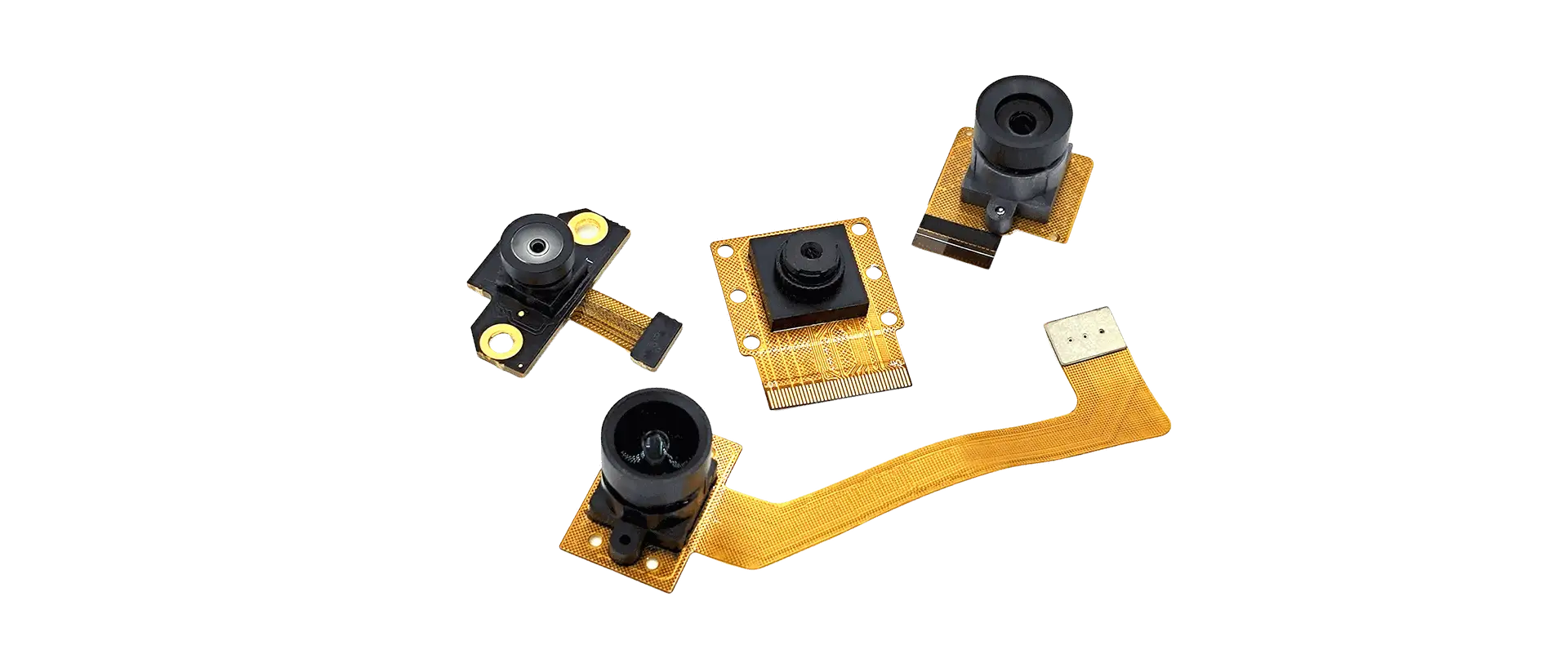

OEM & embedded vision camera modules from 0.3MP to 200MP - USB, MIPI CSI-2, GMSL, DVP, SPI - ready to integrate or fully customized..

Supplying Camera Modules to Product Makers Worldwide

Established

Factory area

Monthly production capacity

Options

Step inside Camemake’s state-of-the-art camera module production facility. From cleanroom optical assembly to precision sensor calibration and final quality testing, every stage happens under one roof. Our factory runs 24/7 with the capacity to produce over 30 million units per month, ensuring consistent quality and rapid delivery for OEMs, makers, and innovators worldwide.

🎥 Watch now and see how we turn concept designs into high-performance USB, MIPI, DVP/SPI, Raspberry Pi, and NVIDIA Jetson camera modules — ready for your next project.

Camera Modules for Every Product Build

USB Camera Modules

Our USB camera modules are plug-and-play UVC devices designed for seamless connection to PCs, single-board computers, and embedded systems. We manufacture modules from 0.3MP to 200MP, with both rolling shutter for general imaging and global shutter for high-speed or motion-critical applications.

Choose from USB 2.0 for compact, low-power builds or USB 3.x for high bandwidth, 4K+, and high-frame-rate streaming. All modules are available with M-size lenses down to M1, offering narrow telephoto for detail capture, ultra-wide 260° fisheye, or 360° panomorph for complete scene coverage.

Typical applications include video conferencing, industrial inspection systems, robotics, kiosks, access control, smart retail, and more. We offer both standard modules ready to ship and fully customized USB designs to match your mechanical and optical needs.

MIPI CSI-2 Camera Modules

Camemake’s MIPI CSI-2 modules connect directly from image sensor to your SoC ISP, ensuring minimal latency and maximum image fidelity. Designed for platforms such as Raspberry Pi, NVIDIA Jetson, NXP, Rockchip, and custom boards, they support resolutions from HD to multi-megapixel, with rolling or global shutter options.

Our designs are compact and flexible, with M-size lenses down to M1 and field-of-view options from narrow telephoto to 260° fisheye or 360° panomorph. We also provide HDR tuning, low-light optimization, monochrome sensors, and IR-pass/IR-cut variants to fit demanding imaging environments.

From industrial machine vision to AI-powered robotics, our MIPI modules are engineered for reliability and performance — whether you choose a stock design or commission a custom module built to your exact specifications.

Endoscope Camera Modules

When space is tight, our endoscope camera modules deliver high-quality imaging in diameters as small as 0.6 mm. Built with M-size optics and available with low-distortion, short working distance lenses, they’re ideal for inspection tools, measurement devices, borescopes, and precision assembly aids.

Modules are available in rigid, flexible, or rigid-flex PCB formats, with options for USB, MIPI, or DVP/SPI interfaces. We can adapt cable lengths, connectors, and lens parameters to fit your housing, ensuring seamless integration into your tool or product.

With our in-house cleanroom manufacturing and optical alignment processes, even modules at this scale meet the same QA standards as our largest camera designs.

DVP/SPI Camera Modules

For microcontroller-based projects, DVP and SPI camera modules provide simple, low-pin-count connectivity while keeping power consumption minimal. Perfect for Arduino, ESP32, STM32, and other MCU platforms, these modules are used in IoT devices, educational kits, low-cost imaging products, and rapid prototyping.

We offer resolutions from VGA to several megapixels, with fixed-focus lenses, compact footprints, and lightweight FPC or rigid PCB designs. For volume production, we customize cable lengths, connectors, and optical setups to match your enclosure and electrical layout.

Whether you need a simple proof-of-concept camera or a production-ready DVP/SPI module, Camemake can supply it with consistent quality and delivery timelines.

Raspberry Pi MIPI Camera Modules

Developed specifically for the Raspberry Pi 5 pinout, these compact modules integrate level shifters and crystal directly on the FPC — eliminating the need for extra adapter boards. We also produce variants for older Pi models, with full mechanical and electrical compatibility.

Available with M-size lenses from narrow telephoto to wide fisheye and 360° panomorph, our Raspberry Pi modules support a wide range of image sensors from Sony, OmniVision, onsemi, SmartSens, and others.

Ideal for makers, product developers, and OEMs, they deliver high performance while remaining easy to integrate into Pi-based AI vision, robotics, and industrial monitoring systems.

NVIDIA Jetson MIPI Camera Modules

Built for the 22-pin, 0.5 mm pitch MIPI CSI-2 interface on Jetson Orin Nano, Orin NX, and AGX Orin, these modules connect directly without adapters. Onboard sensor, level shifters, and crystal make for a clean, compact FPC-mounted design.

We offer global and rolling shutter options, HDR and low-light tuning, and full M-size lens coverage from M1 telephoto to 260° fisheye and 360° panomorph. All modules are tested for compatibility with NVIDIA JetPack and DeepStream SDK.

From autonomous robotics to AI-enabled machine vision, Camemake’s Jetson modules deliver production-ready imaging that scales from prototype to high-volume deployment.

The Partner Behind Your Camera Module

Direct From the Manufacture

We design, assemble, and test all camera modules in-house. From SMT and cleanroom optical alignment to final QA. This gives you full traceability, consistent quality, and competitive lead times.

Broad Sensor Portfolio

We work with Sony, OmniVision, onsemi, SmartSens, GalaxyCore, Himax, and others. This means you get the right sensor for your resolution, frame rate, and light performance, without being locked into one supplier.

Full Optics Control

Our in-house lens selection covers all M-size lenses, including M1 ultra-compact optics. Field of view options run from narrow telephoto to 260° fisheye and 360° panomorph, plus IR-pass, IR-cut, and low-distortion variants.

Interface Coverage

From high-speed USB 3.x to low-power DVP/SPI, and from MIPI CSI-2 for embedded AI to USB 2.0 for plug-and-play devices, we have the interface your design needs and we can customize it to fit.

From Prototype to Mass Production

Whether you need 10 modules for a proof-of-concept or millions for a product line, our production system scales with you. We keep long-term supply in mind, offering lifecycle planning and last-time-buy notifications.

Global Supply & Support

With operations in Asia, Hong Kong, and Europe, we ship camera modules to over 50 countries and support customers across time zones, from engineers to procurement teams

Industrial Automation & Robotics

Camemake camera modules are at the heart of advanced industrial automation systems and robotics platforms worldwide. Our global shutter sensors — including Sony Pregius and onsemi AR series — deliver sharp, distortion-free images for high-speed pick-and-place machines, conveyor belt quality inspection, automated optical inspection (AOI), and robotic arms performing delicate assembly. The compact M-size lens format allows integration into tight mechanical spaces, while MIPI CSI-2 and USB 3.x interfaces ensure low-latency, high-bandwidth data transfer to industrial controllers and AI processing units. We also offer HDR optimization, low-light tuning, and custom FOV design to adapt to different manufacturing environments, from brightly lit electronics plants to variable-light warehouse robotics. .

Access Control & Self-Service Kiosks

Our UVC-compliant USB camera modules and MIPI CSI-2 designs are built for access control terminals, smart gates, ticketing systems, and self-service kiosks in airports, offices, public transportation, and secure facilities. With support for facial recognition algorithms, QR/barcode scanning, document imaging, and thermal fusion when combined with IR sensors, these modules ensure reliable performance in mixed lighting conditions. Using IR-cut filters, HDR sensors, and optimized lens coatings, we deliver clear, accurate imaging even in strong backlight or nighttime operation. Mechanical customization allows modules to fit ultra-slim bezels and vandal-resistant housings without compromising image quality.

AIoT – Artificial Intelligence of Things

AIoT represents the convergence of AI-enabled camera systems with the Internet of Things, and Camemake is a leading supplier of modules tailored for edge computing. Our designs are optimized for Raspberry Pi, NVIDIA Jetson, NXP i.MX, Rockchip, and other AI SoCs, making them ideal for low-latency, real-time image analysis at the edge.

We support a broad range of AIoT verticals:

- Smart Cities: Traffic flow monitoring, license plate recognition (ANPR), illegal parking detection, waste bin fill level monitoring, and crowd counting.

- Smart Retail: Shelf monitoring, out-of-stock detection, planogram compliance, customer demographic analysis, and theft prevention using AI vision.

- Smart Home: AI-powered video doorbells, indoor activity monitoring, elderly care monitoring, and pet recognition systems.

- Smart Agriculture: Crop growth tracking, pest identification, irrigation optimization using NDVI imaging, and yield prediction.

-

Smart Manufacturing: Predictive maintenance using visual inspection, process anomaly detection, and safety compliance monitoring.

With features like wide dynamic range (WDR), low-light sensitivity down to 0.01 lux, global and rolling shutter options, and M-size lens adaptability, our AIoT-ready camera modules deliver the image data that machine learning models depend on for accurate results.

Applications of Camemake Camera Modules

Smart Retail & AI Analytics

Camemake modules empower in-store analytics systems with wide-FOV, high-resolution imaging for customer tracking, queue monitoring, and heat mapping. Our MIPI CSI-2 modules connect directly to AI edge devices like Jetson or Raspberry Pi, reducing processing latency and improving recognition accuracy. We supply monochrome and IR-pass modules for privacy-compliant analytics where facial detail is not required but movement and behavior still need to be tracked. HDR tuning ensures usable images under the mixed lighting common in retail environments, from bright shopfront windows to dim aisles.

Wearables & Portable Devices

From body-worn cameras for security personnel to AR/VR headset modules and handheld scanning tools, Camemake designs compact, low-power cameras that fit the form factor and battery constraints of portable electronics. Custom lenses and custom FPC layouts ensure comfort and proper balance in wearables, while low-power USB and MIPI CSI-2 connections extend device runtime.

Automotive & Mobility Solutions

Camemake modules are integrated into driver monitoring systems (DMS), in-cabin passenger analytics, and road-facing ADAS research platforms. With HDR sensors for high-contrast scenes, low-light performance for nighttime driving, and vibration-resistant mechanical design, our cameras deliver consistent image quality in challenging automotive environments. Narrow FOV modules capture focused driver facial data, while wide FOV models provide full cabin or multi-lane road coverage.

Drones & UAV Imaging

Our lightweight, high-performance MIPI CSI-2 modules are used in unmanned aerial vehicles (UAVs) for mapping, surveying, and environmental monitoring. We offer global shutter sensors for motion-free aerial capture, high-frame-rate streaming for FPV (first-person view) systems, and narrow or wide-angle optics depending on mission requirements. Modules are available with low-light performance for dawn/dusk operation and mechanical designs optimized for vibration resistance and weight savings.

Camera Modules Engineered for Diverse Industries & AIoT Solutions

Smartphone & Tablet Imaging Solutions

Camemake camera modules power high-performance imaging in smartphones, tablets, and mobile computing devices. Our ultra-compact designs integrate high-resolution CMOS sensors, multi-lens configurations (wide, ultra-wide, telephoto, macro), and advanced HDR/WDR image processing to deliver sharp, vibrant images in all lighting conditions.

Modules support MIPI CSI-2 and USB-C interfaces for high-speed image transfer, while low-power optimization extends battery life. With OIS stabilization, fast autofocus, and low-light tuning, we enable flagship-level photography and video performance in slim device profiles.

For OEM/ODM projects, we offer custom FPC layouts, computational photography pipelines, and AI-ready image processing for facial recognition, AR/VR integration, and biometric security. From consumer smartphones and tablets to industrial rugged handhelds, Camemake delivers compact, efficient, and premium-quality camera modules.

Customization & OEM–ODM Camera Modules

From Concept to Production — Cameras Built for Your Product

While we offer ready-to-buy modules for fast evaluation, over 98% of our production is custom-designed for specific products. Camemake works with OEMs, startups, and product developers to create camera modules that meet exact optical, electrical, and mechanical requirements — from prototype to high-volume mass production.

What We Customize

Our engineering teams adapt every aspect of the module so it works flawlessly in your application:

- Image Sensors: Sony, OmniVision, onsemi, SmartSens, GalaxyCore, Himax — chosen for resolution, frame rate, low-light, or global shutter requirements.

- Optics: All M-size lenses, from ultra-compact lenses to 260° fisheye and 360° panomorph. Low distortion, IR-pass/IR-cut, telephoto, and specialty optics available.

- Interfaces: USB 2.0 / 3.x for UVC devices, MIPI CSI-2 for embedded AI, DVP/SPI for microcontrollers.

- Form Factors: Rigid PCB, FPC, or rigid-flex designs; custom dimensions, connector position, and mounting hole patterns.

- Environmental Design: Dust/moisture sealing, vibration-resistant mounts, and temperature-hardened builds.

- Firmware & Calibration: Autofocus or fixed-focus alignment, white balance tuning, HDR optimization, and full factory calibration reports.

Our Proven Process

- Definition – We begin with your product requirements, CAD drawings, and target performance specifications.

- Prototyping – Build fully functional samples for field testing and optical validation.

- Refinement – Adjust optics, sensor choice, and firmware for consistent results.

- Production – Manufacture at scale in Class 100 and Class 10,000 cleanrooms, with serial tracking and batch QA.

- Ongoing Support – Lifecycle management, EOL planning, and design updates as needed.

Whether you’re designing a consumer wearable, industrial robot, AI vision system, or inspection tool, Camemake ensures that the camera module is built for your environment, your product, and your market.

Top questions answered

Your Questions Answered

We are the direct manufacturer of all CameMake camera modules. Design, assembly, optical alignment, and final QA are done in-house in our Class 100 and Class 10,000 cleanrooms. This means consistent quality, full traceability, and competitive lead times.

Yes, most of our production is OEM/ODM custom modules. We adapt optics, sensors, interface, form factor, and firmware to match your product’s exact requirements.

We design modules for USB 2.0 / 3.x, MIPI CSI-2, DVP, and SPI and can offer GMSL solutions, covering both high-performance embedded systems and low-power microcontrollers. Our USB modules are fully UVC compliant for plug-and-play operation.

We work with Sony, OmniVision, onsemi, SmartSens, GalaxyCore, Himax, and other reputable sensor brands. Sensor choice depends on your resolution, frame rate, shutter type, and light sensitivity needs.

For ready-to-buy modules, MOQ can be as low as 10 unit for testing. For custom OEM production, typical MOQs start around 500–1,000 units, depending on the complexity of the design and the MOQ of the image sensor itself.

Yes, we ship to over 50 countries with logistics hubs in China, Hong Kong, and Belgium. We work with DHL, FedEx, UPS, and freight forwarders for bulk orders.

Standard prototypes from existing designs can ship in 1–2 weeks, these can be ordered through our resellers or distribution platforms. Fully custom designs typically take 4–6 weeks from final specification approval to delivery.

Every module passes through optical calibration, electronic testing, and mechanical inspection. Batch-level QA reports and serial number tracking are available for OEM customers. Following ISO9001 standards.