At CameMake, we've built our reputation by delivering OEM and custom‑designed camera modules that power robotics, AIoT devices, industrial inspection, medical tools, and more. While many design decisions are obvious—sensor selection, lens system, interface type—one subtle but critical choice often flies under the radar: the color of the PCB itself. Here’s why we always use black PCBs for our camera modules—and how it ensures cleaner, more reliable imaging in all conditions.

The Hidden Risk of Colored PCBs

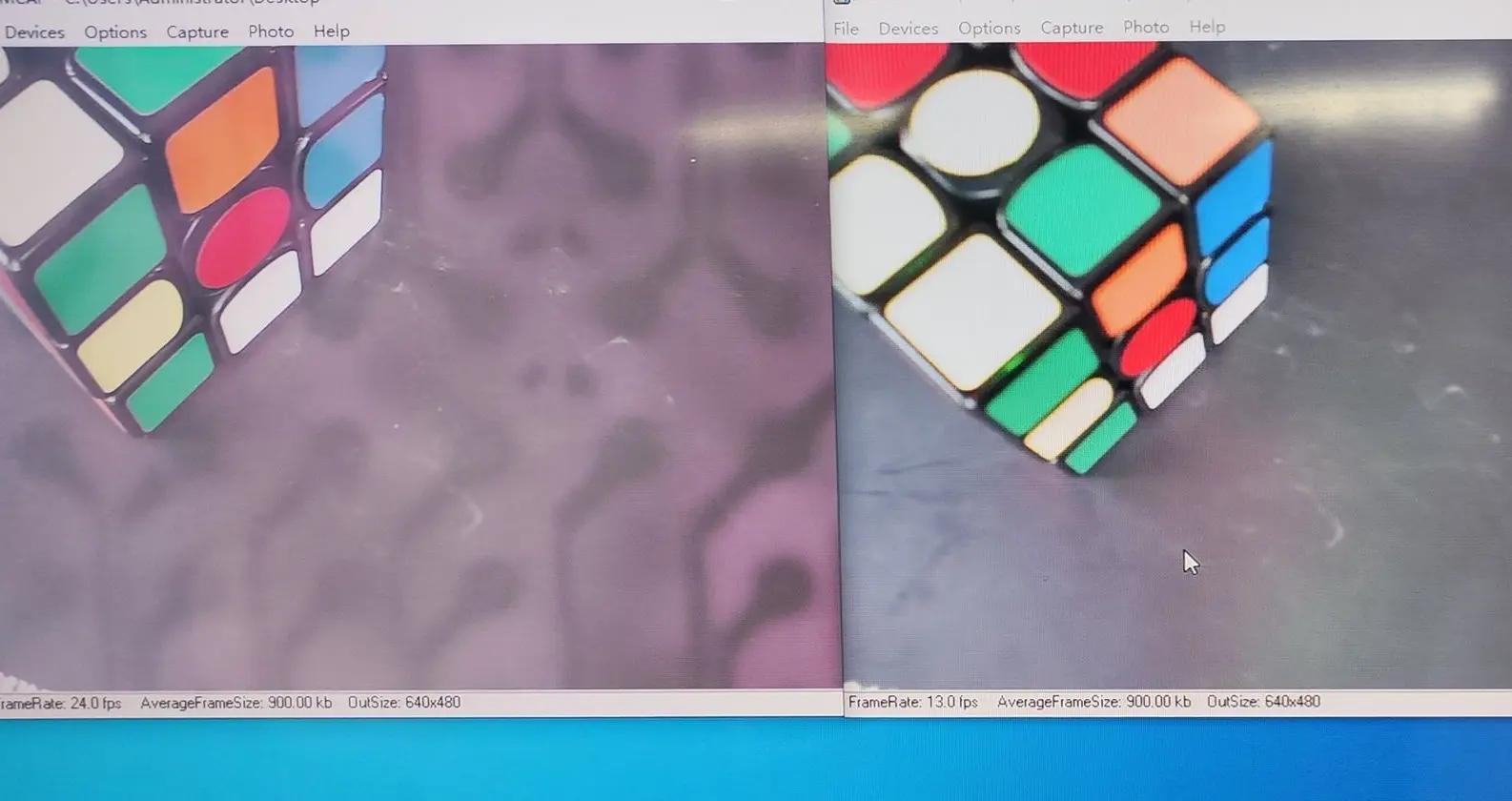

Non‑black PCBs—like green, blue, or red—can leak light when illuminated from the back, especially in infrared (IR) or strong white light scenarios. This transparency enables light to bypass the lens and directly reach the image sensor, causing ghostly artifacts: internal traces and components appear on the captured image—even when not in the main field of view.

This visual proof highlights a major problem: image contamination, color distortion, and reduced image quality—especially in professional, industrial, or AIoT applications.

Why Black PCBs Are the Professional Choice

At CameMake, reliability and precision are non‑negotiable. Here’s why black PCB designs are central to our engineering philosophy:

- Light Blocking: Black solder masks absorb IR and visible light, preventing internal glow from contaminating the image.

- Consistent Imaging: Whether in controlled factory lighting or real-world low-light environments, black PCBs eliminate variability in image quality.

- Brand Credibility: Clean, artifact-free images reflect the high standards of CameMake's modules—critical for OEM partners and innovators.

The Material Science Behind PCB Colors

Many people assume PCB color is simply a matter of aesthetics, but the solder mask pigment plays a functional role in optical behavior.

-

Non-Black Colors (Green, Blue, Red, etc.):

These pigments reflect and scatter light rather than fully absorbing it. Under IR illumination, they become partially translucent, allowing light to penetrate the fiberglass substrate and bounce around the internal copper layers. The result is a faint but visible “map” of the PCB structure showing up in camera images. -

Black Solder Masks:

Black absorbs a broader spectrum of both visible and infrared light. This prevents light leakage through the board and ensures that the image sensor is only exposed to light passing through the lens system, not stray backlight. Black PCBs also reduce the risk of internal reflections that can confuse auto-exposure or auto-white-balance algorithms in camera firmware.

Additionally, manufacturing tolerances differ: non-black PCBs sometimes exhibit higher variability in surface finish reflectivity, which can further impact optical stability. Black solder mask, being uniform and non-reflective, guarantees more predictable performance in optical systems.

How This Fits into CameMake’s End-to-End Quality Process

From initial concept to mass production, CameMake’s camera modules are engineered for precision and consistency:

- Custom design and DFM ensure every detail—from PCB layout to optical alignment—is optimized for performance

- Cleanroom assembly (SMT, sensor placement, optical alignment, calibration, and QA) guarantees that quality meets expectations for industrial, medical, or AI-driven applications

- By integrating black PCBs, we eliminate a subtle yet critical source of image error—upholding our reputation for excellence.

Ready for Clean, Dependable Imaging?

At CameMake, camera design isn’t just about components—it’s about delivering consistently sharp, reliable imagery for your application. Choosing black PCBs is one of those small details that make a big difference.

Call-to-Action Section

- Ready to start your project? Explore our custom camera modules—USB, MIPI CSI‑2, DVP/SPI, Raspberry Pi, Jetson, or endoscope variants—engineered to spec with image integrity in mind.

- Contact CameMake at sales@camemake.com or visit our website to discuss black-PCB camera solutions tailored for your product’s performance requirements.